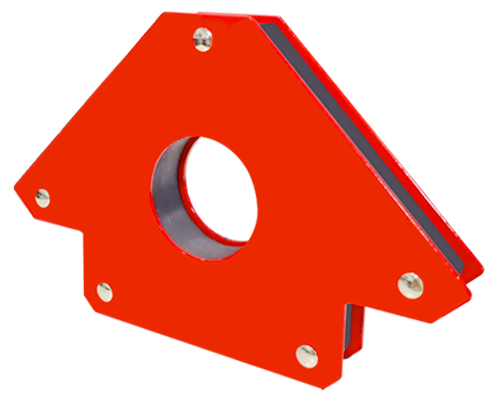

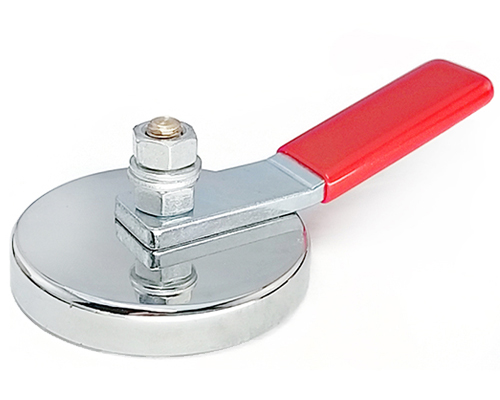

Welding magnets (also called Magnetic welding holders, Magnetic welding clamps) are consist of steel in different shapes and strong magnets, they are used to connect two ferrous metal object together and hold them at a certain angle, in order to make sure the workers can weld them accurately and greatly improve the efficiency.

Welding magnets are a quick and secure solution for positioning and securing steel work pieces, they can attract to any metal or ferrous objects and are strong enough to hold work pieces at different angles, covers 30, 45, 60, 75, 90, and 135 degrees.

Types of Welding Magnets

Manufacturing method

There are a variety of types and sizes of welding magnets, like welding Magnets with switch, multi-angles welding magnets, arrow welding magnets, adjustable welding magnets, magnetic welding clamps, should be specified according to how it will be used and the weight to hold. Mounting holes can be drilled for easy fixing into powerful holding jigs.

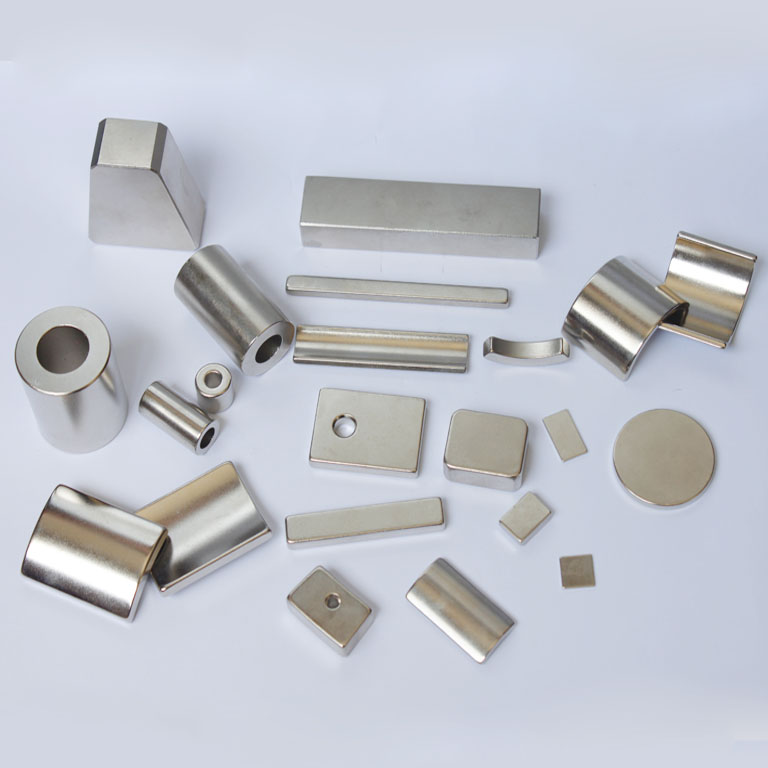

The inside magnets are generally ferrite magnets, while Neodymium magnets, SmCo magnets and AlNiCo magnets are also available. The red powder coating is the standard surface finish to protect from rusting and scratching, customized logo can be printed on the steel body if required.

Applications

Welding magnets are a great tool for welding projects, assembly of components, pipe installations and soldering projects, they are useful to secure pieces of metal together and properly aligned before the weld is complete, additionally they can free up the workman hands to make sure safely working and get above jobs and projects go smoother. Welding magnets are useful for a quick setup and accurate holding for all jobs, and also used to separate steel plates.

中文

中文