Neodymium magnets (also called NdFeB magnets, Neo magnets) are consist of Nd (neodymium), Fe (ferrum), B (boron) and other elements like Dy(dysprosium) and Ti(Titanium), as part of permanent magnet family, they are the latest generation of rare earth magnets.

Neodymium magnets are extremely super strong magnet commercially available in the world, their pull force are quite strong compared to their own size, they have high magnetic remanence, high energy product and relative good coercive, due to these advantages, they are the most widely used magnets today.

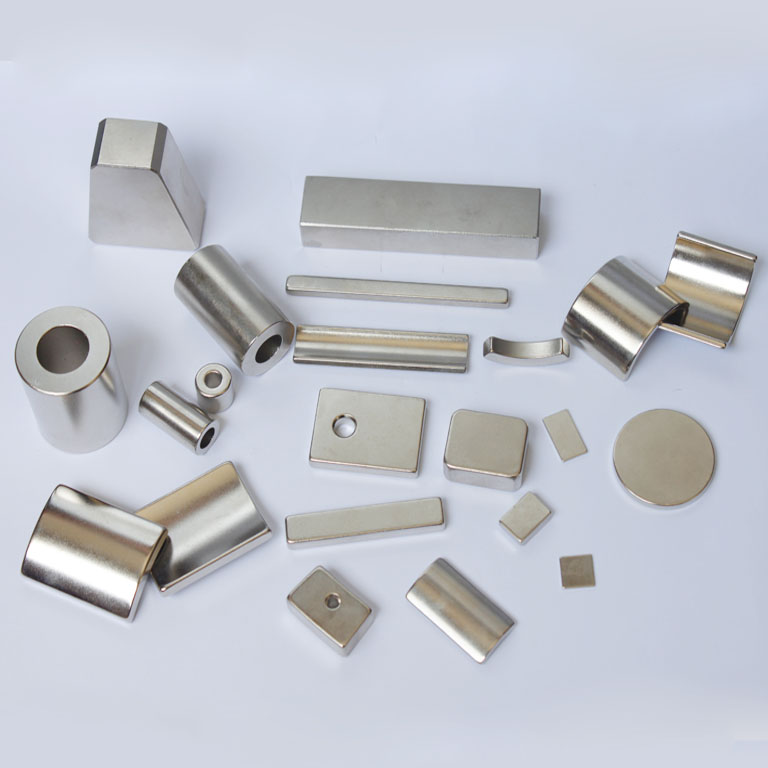

Types of Neodymium Magnets

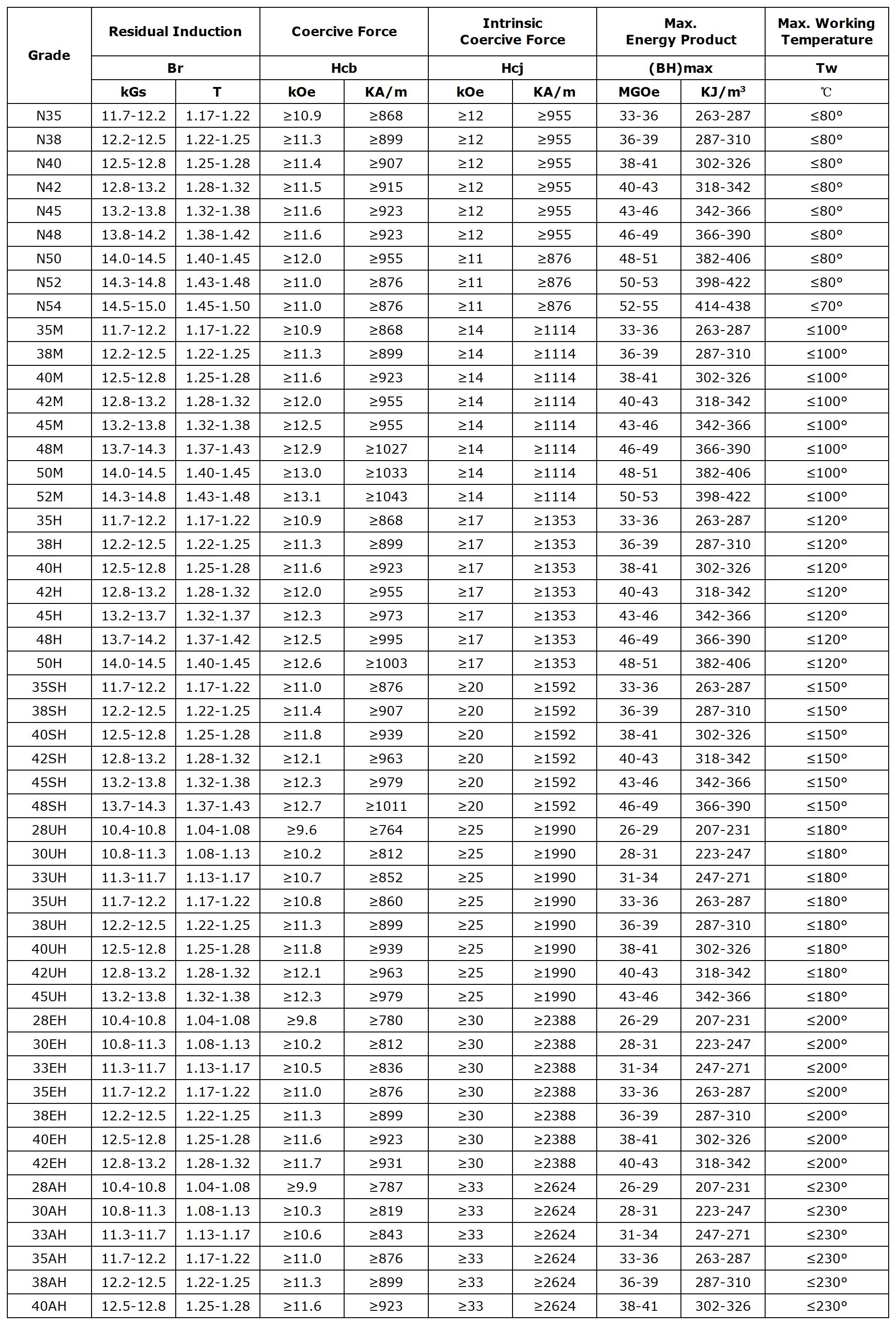

Magnetic properties

We can manufacture and supply all the grades from energy product 35MGOe to 52MGoe and from N series to AH series.

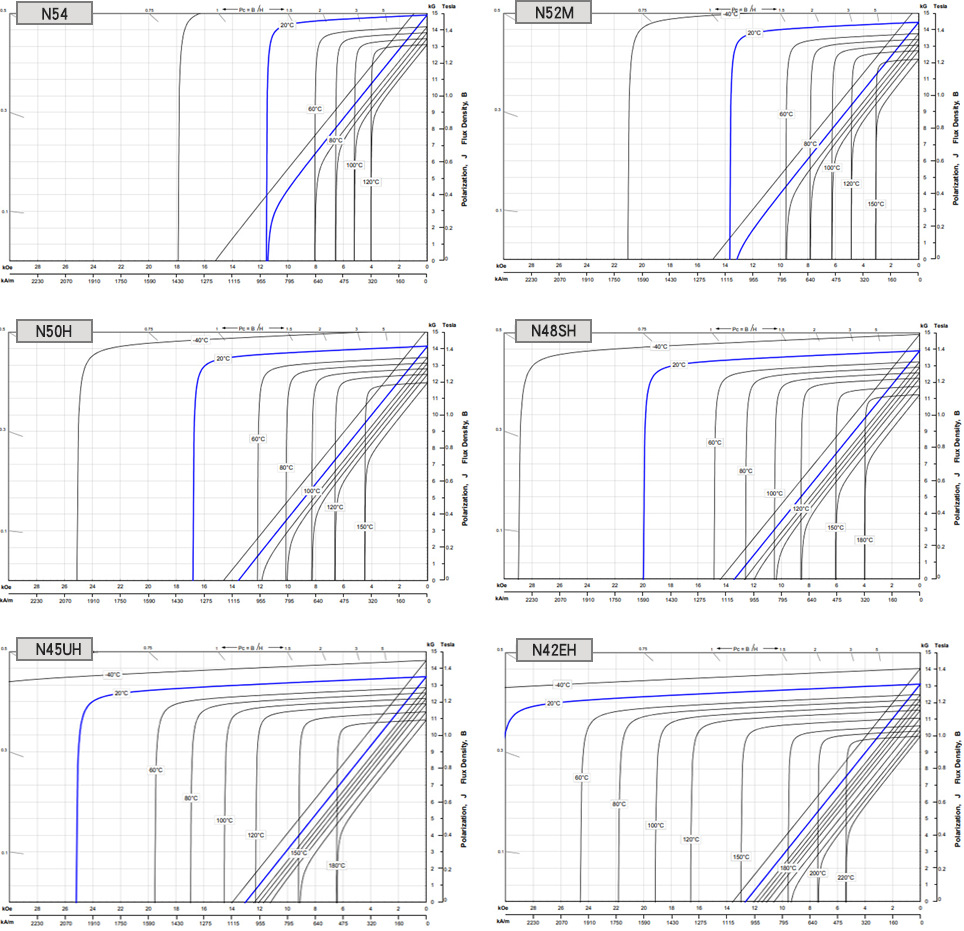

Demagnetization curves

We list the performance of highest grades with different series when demagnetization.

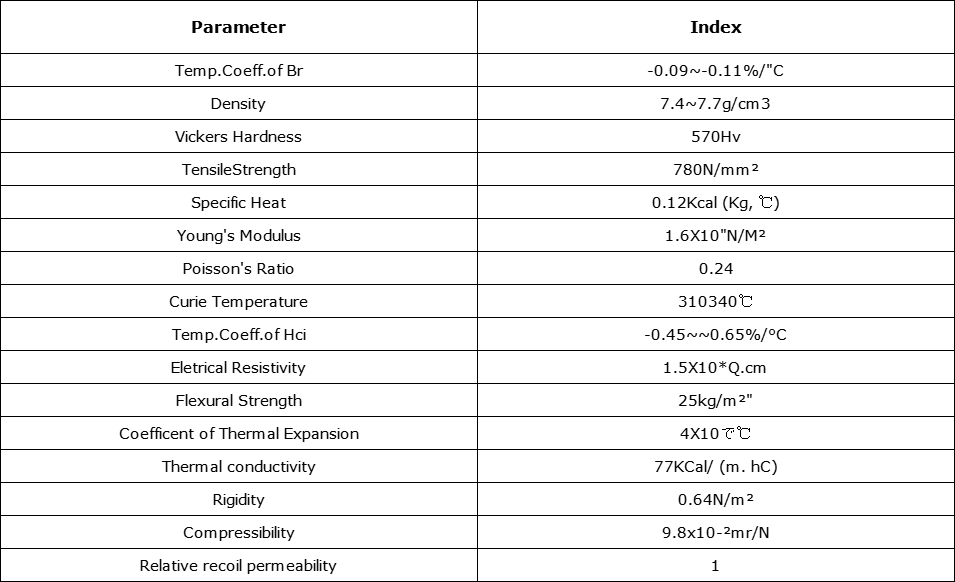

Physical properties

A few main physical properties are listed, like density, curie temperature etc.

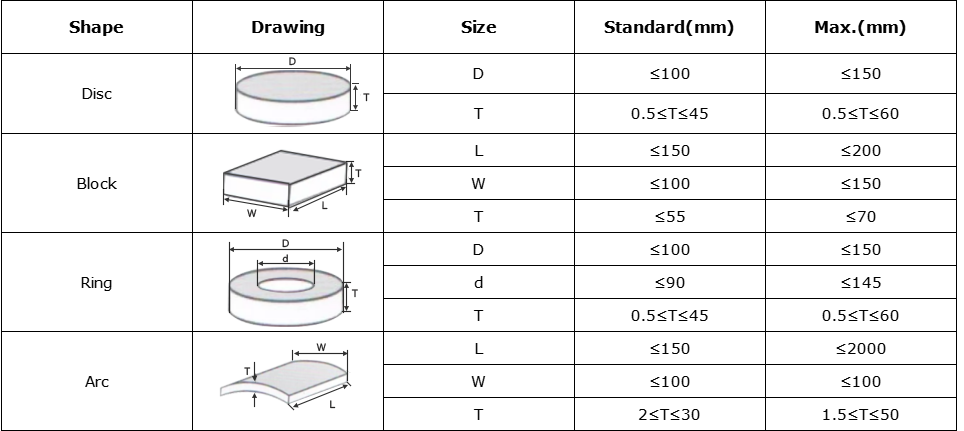

Sizes & Tolerances

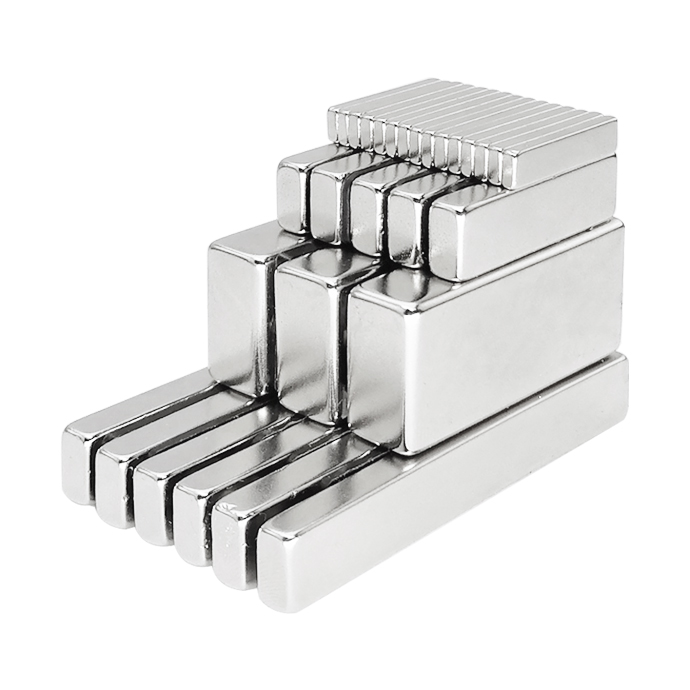

We can produce different shapes, like disc, cylinder, ring, arc segment and custom complicate shapes, a wide range of sizes are possible with a few limits.

The standard tolerances are generally +/-0.1mm, while slightly varies depending on how big the size is.

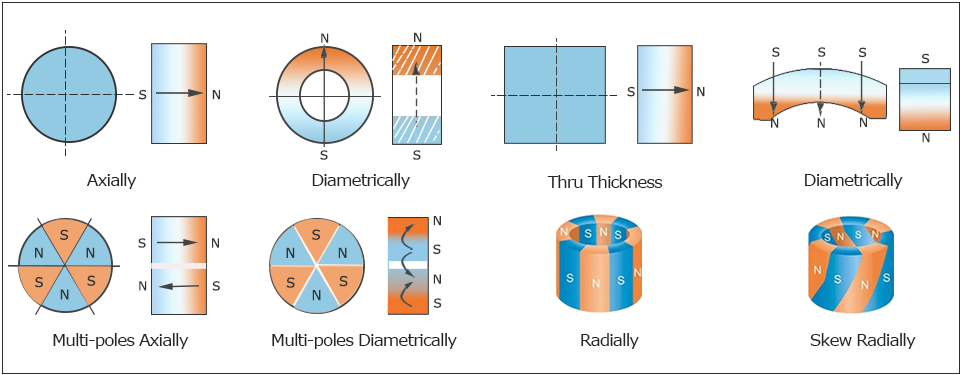

Magnetization

All Neodymium magnets are anisotropic and oriented with a preferred direction during production, they can only be magnetized thru the oriented direction. Disc/cylinder/ring magnets are axially or diametrically magnetized, block magnets are magnetized along one side of three side, arc segment magnets are generally diametrically magnetized.

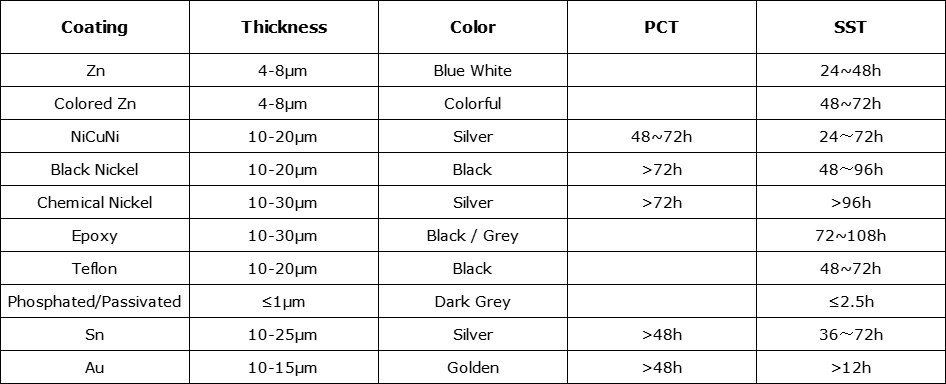

Surface coatings

The corrosion resistance of Neodymium magnets is considered very poor, a surface coating will be necessary, the most common coatings are: NiCuNi, Zn, Black epoxy, Teflon/PTFE, Rubber/Plastic.

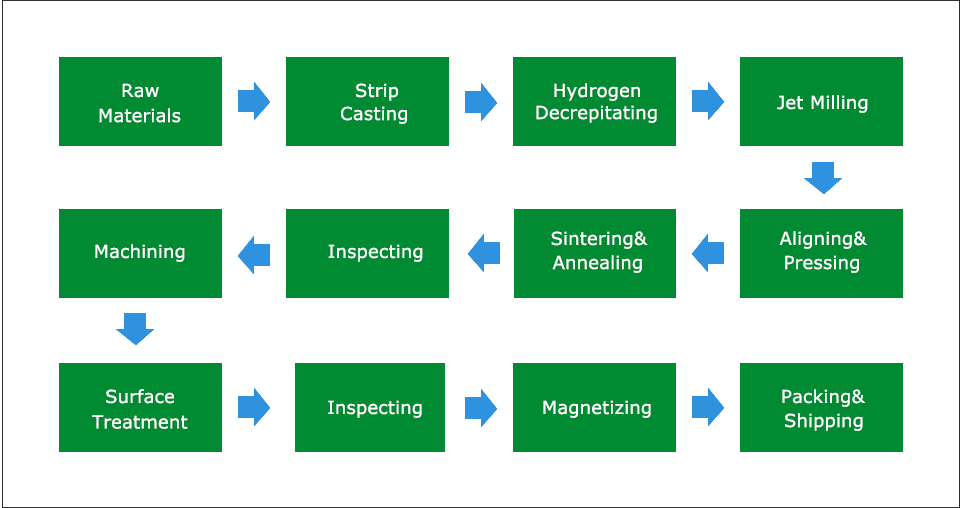

Manufacturing method

Neodymium magnets are made by a sophisticated process using very advanced metallurgical methods, the main process are: Rare earth raw materials - Quick curing - Strip casting - Hydrogen decrepitation - Milling - Pressing - Sintering - BH curve testing - Machining - Plating - Magnetizing - Packaging.

Applications

Neodymium magnets are widely used for industrial, technical, commercial and consumer applications, the most common applications are: motors/generators, sensors, audio equipments, holding/lifting systems, magnetic bearings, hard disc drives, levitation devices, magnetically coupled pumps, medical devices, magnetic separators, packaging closures, commercial signage/display.

中文

中文