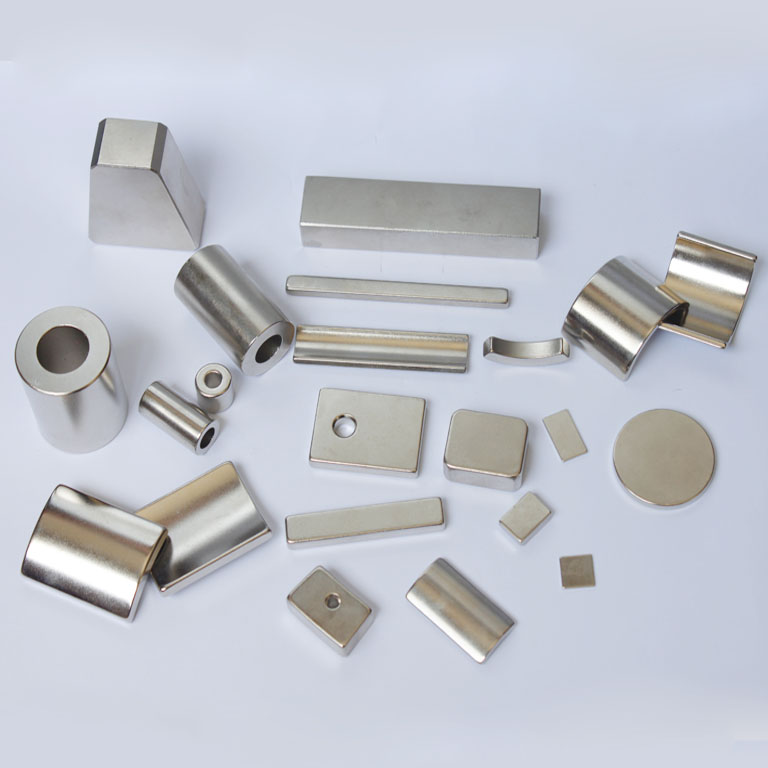

Can you produce custom magnets?

Yes, please provide your specific requirements, we will be pleased to support you to finish the magnet design, we do have the ability to produce custom magnets for you.

Do you require a MOQ?

We don’t require a MOQ, even a sample magnet is acceptable, but a economic price is based on a reasonable quantity.

How long do you need to do a custom magnet order?

Depending on how much complicate the magnet shape is and how much quantity required, generally it will take us 15-30 days to finish the order.

How do you ship the magnets? Is it possible to ship by air?

We can ship the magnets by sea, by truck, by air and by express, you can indicate the shipping method according to the time schedule and shipping charge.

What’s the payment methods?

Generally we accept the payments via wire transfer, while can also accept small payment via Paypal, Alipayor or Credit card.

What’s the strongest magnet?

Neodymium magnet is the strongest magnet series in the world, it has different grades with maximum energy product from 35 MGoe to N54 MGOe, the grade N54 is strongest grade of Neodymium magnet.

How is the magnetic pull force measured?

We use a tensile tester to measure the pull force in our lab, our pull force is got at the most ideal condition, while the actual pull force is quite different when used in different applications.

Will the magnets lose their magnetic force?

Unless the magnets are damaged, for example demagnetized by strong magnetic field, used in high temperature , corroded by salt water, the magnets won’t lose magnetic strength and can keep almost the same strength for over 10 years.

Can I cut, drill, weld the magnets on our side?

No, we don’t recommend to do machining magnets on your side, as the magnets are very brittle, it will be damaged quickly.

What’s the maximum working temperature of magnets?

The maximum working temperature of different magnets are quite different, the series N-M-H-SH-UH-EH-AH of Neodymium magnets are with maximum working temperature from 80 to 200 degree C, while the series Sm1Co5 and Sm2Co17 of SmCo magnets are with maximum working temperature from 250 to 350 degree C.

Are surface coating necessary for magnets? What kind of coatings are available?

Neodymium magnets will corrode very quickly without coating, a coating is necessary to protect it against oxidization, while SmCo magnets are generally supplied with no coating, as it doesn’t contain any composition easily oxidize. The standard coatings for the magnets are NiCuNi, Zn, Black Epoxy.

中文

中文