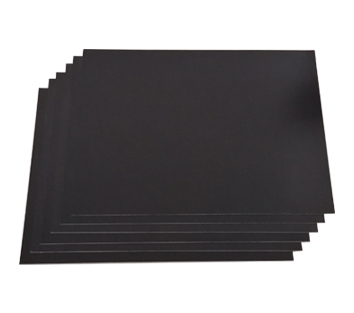

Magnetic sheet (the main kind of flexible magnets) is made of strontium ferrite powder compounded with plastics or rubbers (NBB or CPE) by calendering proess. There are 3 grades of magnetic sheet: Isotropic, Semi-anisotropic, Anisotropic, although the magnetic properties with (BH)max from 0.6 MGOe to 1.6 MGOe, special magnetic properties can be produced once the MOQ is met.

The main characteristics of magnetic sheet is soft and flexible, it can be easily cut to any shape, bent, twisted, coiled, no loss of magnetic properties will happen during this.

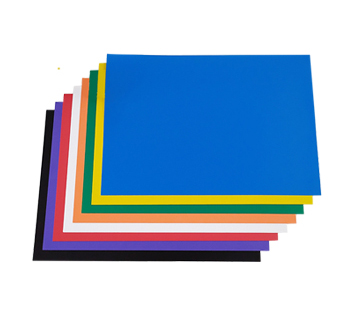

Types of Magnetic Sheet

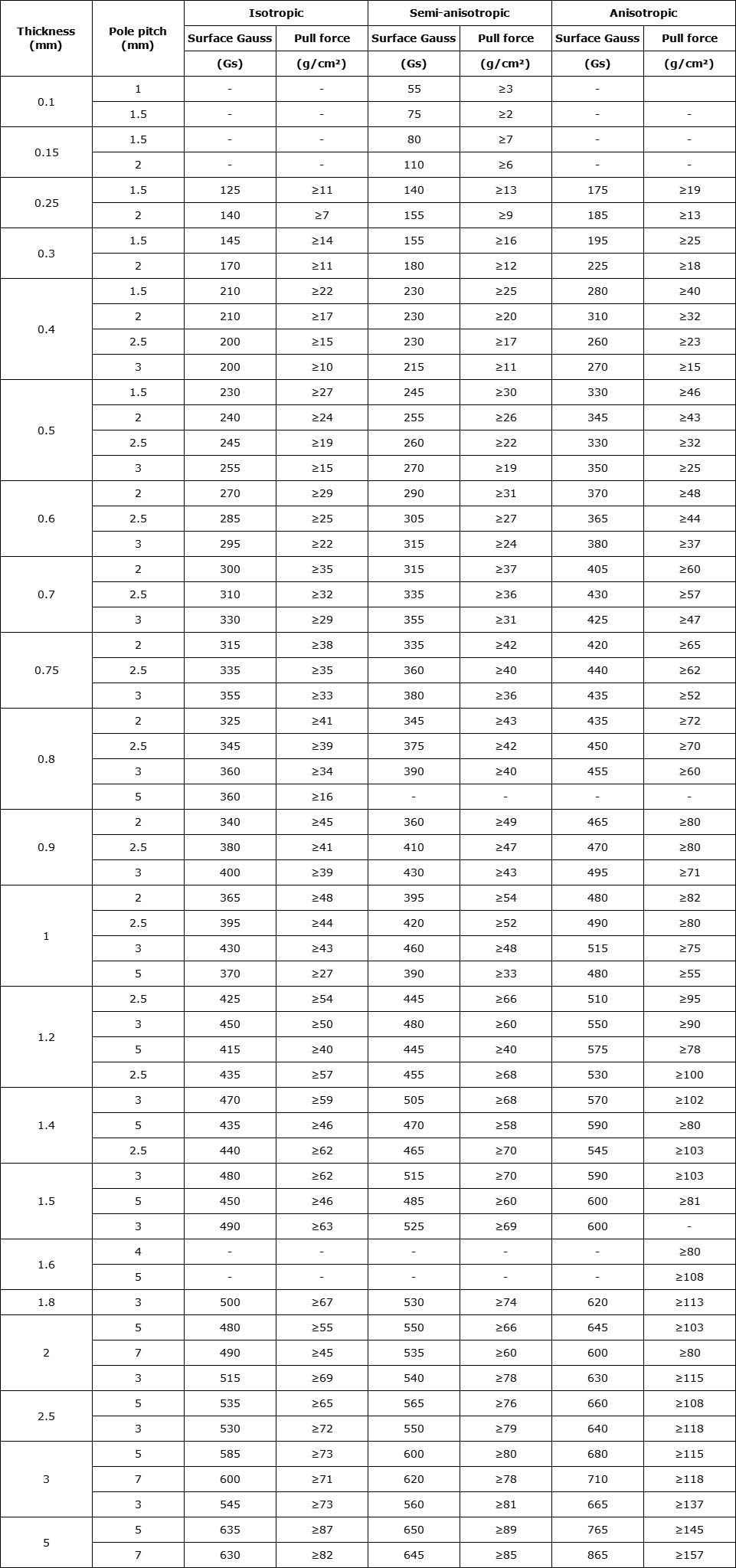

Magnetic properties

Manufacturing method

The production ways of magnetic sheet is that, firstly the materials are calendered in wide format rolls, the standard sizes are: thickness(0.4mm, 0.5mm, 0.75mm, 1mm, 1.5mm), width(620mm, 1000mm, 1200mm, 1370mm) and length(10m, 15m, 20m, 30m). Special roll size can be custom made, also can be cut to small sheet like A3 and A4 size.

Magnetic sheet is always multiple poles magnetized on single face with magnetic pitch 1.5mm, 2mm, 2.5mm, 3.0mm or 5.0mm. Though magnetized thru thickness is also possible for magnetic sheet if it is required for special applications, each a single pole will be on each face at this condition.

The non-magnetic face of magnetic sheet can be plain or laminated with PVC, self-adhesive, dry-wipe PET, PP upon request, while the magnetic face is generally with UV coating.

Applications

Magnetic sheet is widely used in various commercial and industrial applications, mainly for Automotive Signs, Business Cards, Commercial Signage, Crafting Projects, DIY Home Improvement, Fridge Magnets, Large Format Graphics, Name Badge Holders, Office Presentations, Packaging Closures, Paint Masking Applications, POP & Tradeshow Displays, Promotional Giveaways, Warehouse Labeling, Windows & Door Seals.

中文

中文